ADSORBENT

Hydrogen Production / Storage

-

Hydrogen Production

Raw materials

LNG, LPG, OIL, coal, water, ammonia, etc.

Materials that contain hydrogen(H)

Reforming plant

Water electrolysis -

Ammonia Reformation

AC (Solid Ammonia) -

High Purity Hydrogen

High Purity Hydrogen -

Hydrogen Storage

Hydrogen Tank

/ LOCH

/ Chemical StorageMetal hydrideAB2(Solid Storage) -

Liquid Hydrogen Fuel Cell

H2 Car Fueling Station

Fuel Cell

H2 Car Fueling Station

Business

-

Large area of service coverage

Response to low level alerts

Maximum Safety, Core Technology

-

Hydrogen Production from Ammonia Reformation

-

AB2 Solid Storage

Easy hydrogen storage, charging, and discharging

Maximum Convenience

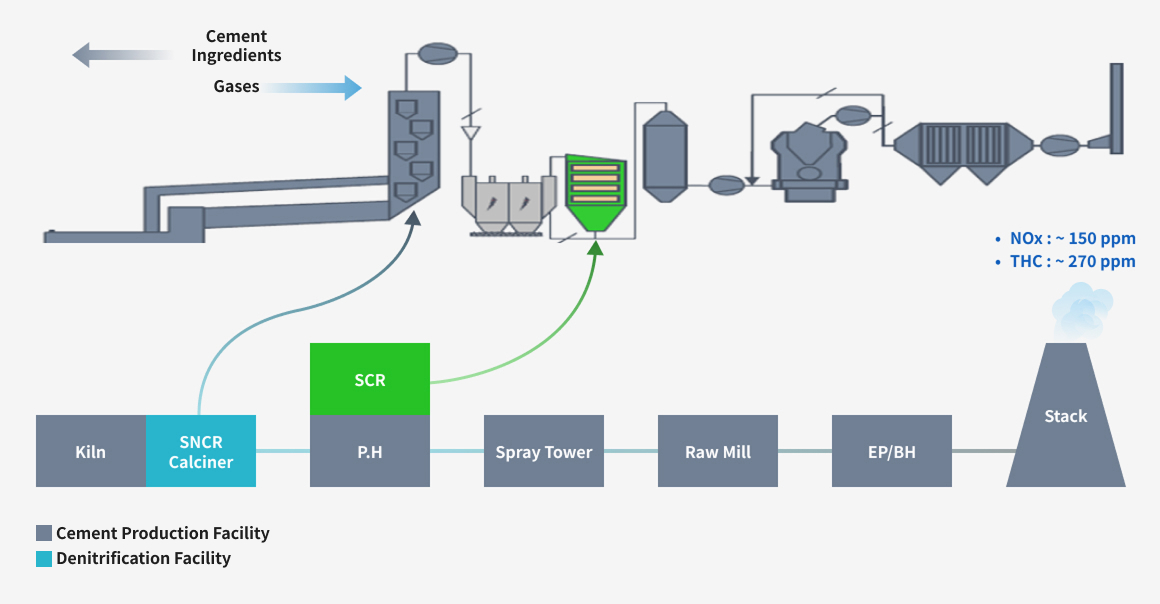

Status of Current Technology for NOx Removal from Cement Production : SNCR and SCR will be implemented simultaneously to reduce nitrous oxide from cement production (Ministry of Environment)

*Target Denitrification

Efficiency(%) : ~70

PROBLEM

- Strengthening Regulations : 240 ppm upper limit and 98 ppm lower limit by 2027

- Technical limitations : need to secure SCR catalyst durability in high emission environment/within the next 6 months

- Economic limitations : expected to exceed 10 billion per initial kiln installation, and expected to exceed 5 billion in annual maintenance costs

Cement ingredient base nitrogen adsorbents

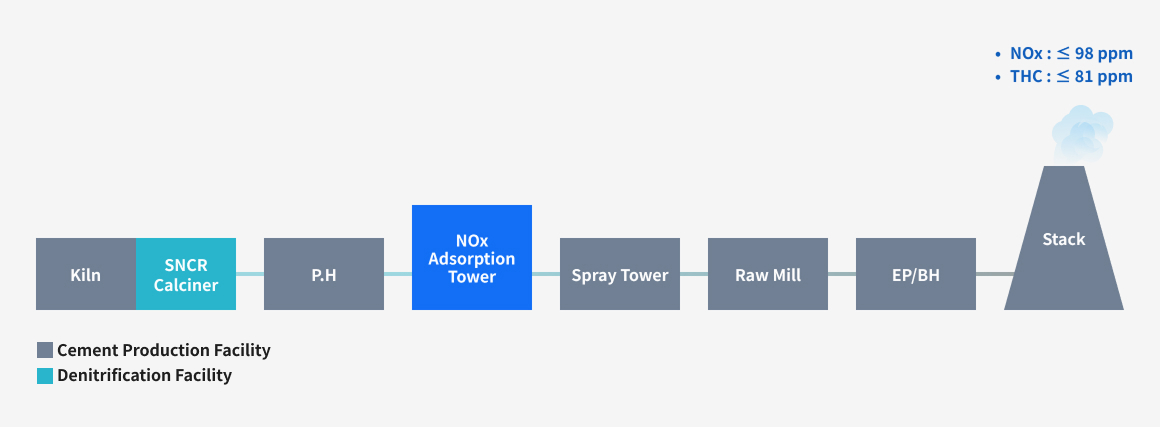

HYDROCHEM’S New Denitrification Process (SNCR + NOx Adsorption)

* Denitrification Efficiency(%): 70~

SOLUTION

- Technology Overview : Adsorption material with NOx adsorption for cement ingredients

→Add NOx adsorption to Ca(OH)₂ Base - Technology : Does not affect the cement production process, and has excellent adsorption at high temperatures

- Affordability : Estimated one-half cost compared to standard SCR systems

- ZERO EMMISION : The adsorbent is 100% used in cement production

- Perfect response to tightening regulations

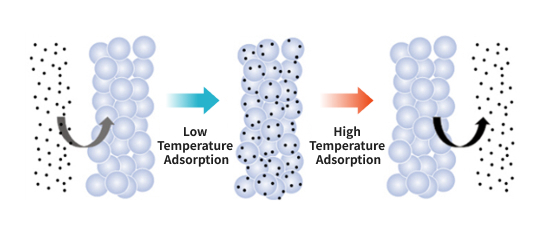

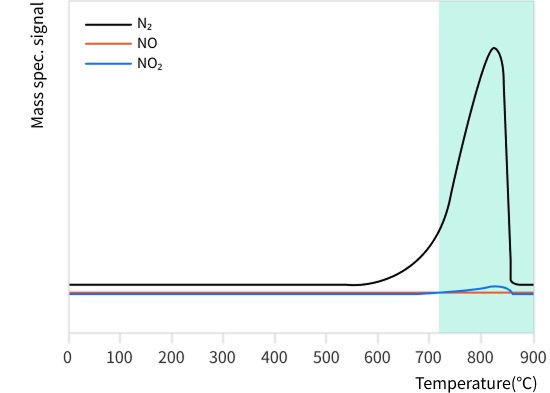

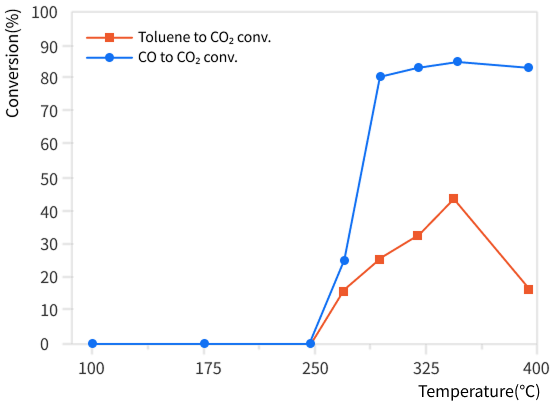

NOx Adsorbent Properties : Adding adsorbents to cement production can adsorb NOx and THC simultaneously

Adsorbent Basics

Adsorbent Properties

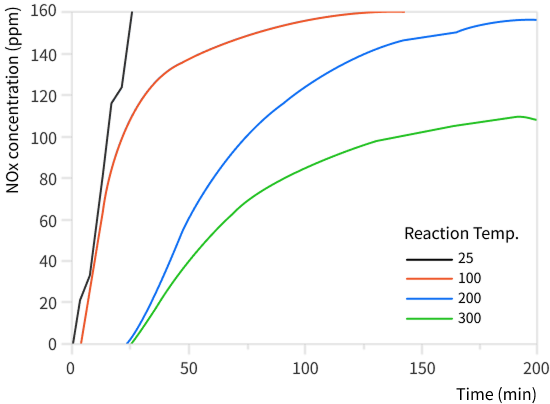

- Increased adsorption capacity at temperatures below 350°C

- NOx is desorbed to N2 at 550°C or higher

- THC removed by additional oxidation between 300°C and 350°C

- Ca(OH)2 based materials can be reused as cement ingredients, fertilizer, etc.

NOx Adsorption by Temperature

THC Deoxidation Properties

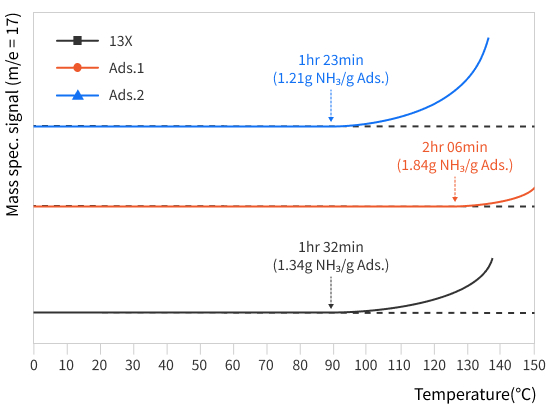

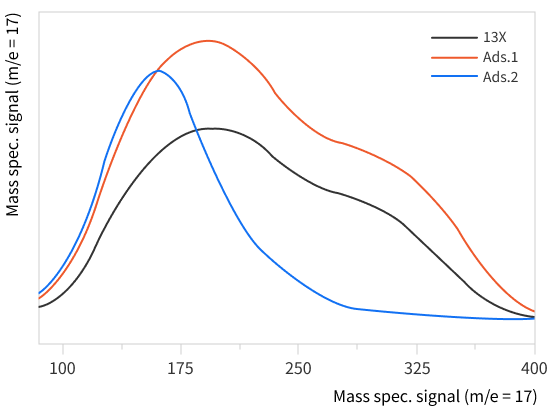

NH3 Adsorbent Properties : A widely used ammonia based adsorbent for it’s excellent adsorption and durability.

| Product Name | HC_Ads.1 | HC_Ads.2 |

|---|---|---|

| Product |  |

|

| Adsorbent Target | NH3 | NH3 |

| Adsorbent Components | Zeolites | Zeolites |

| Adsorbent Efficiency | Approx. 1.4 times absorption rate compared to 13X | Similar Adsorption rate to 13X |

| Adsorption Temperature | 13X와 Similar temperature to 13X |

Approx. 50°C lower than 13X |

NH3 Adsorption Efficiency

Breakthrough Trial

(NH3 3,000ppm Adsorption Trial)

Recycling Trial

[Technology 1] Hydrogen Production

/ Storage (AC Solid Ammonia)

Requirements of the Technology

-

Needed for combating climate change and greenhouse gases

-

Requires water electrolysis H2 storage medium for new/renewable energy

→ Green NH3 Fuel -

NH3 Fuel

→ Need to solve the safety risks and hazards

Advantage

Easy Storage and Transport

Easy NH3 Reformation

Easy CO2 Capture

Easy AC Manufacturing

Concept of Technology 1.

NH3 Transport Media AC

-

NH3 to H2

NH3 to H2

-

NO TICKET (Urea)

① Toxicity

② Flammable

③ High Energy Cost (Urea to NH3, Sewage Treatment)

④ High Manufacturing Cost (CO2 + NH3 to Urea)TICKET (AC)

① Safety

② Low Energy Cost (AC to NH3)

③ Low Manufacturing Cost (CO2 + NH3 to AC) -

N2 & H2 to NH3

CO + NH3 to AC

Concept of Technology 2.

A2A system (AC to Ammonia system)